Dielectric strength of transformer oil

The dielectric strength of transformer oil is one of the main parameters the value of which can serve as a measure of the quality and the current condition of liquid transformer insulation. Physically, dielectric strength means the minimum electric field intensity which causes a liquid dielectric breakdown. As a rule, the dielectric strength unit of measurement is a volt per centimeter (V/cm). The dielectric strength of liquid dielectrics in general and transformer oil in particular has been under study for a hundred years and beyond.

What does the dielectric strength of transformer oil depend on?

The dielectric strength of all the fresh transformer oils with the water and other impurities removed is high — over 210 kV/cm. It is known that the dielectric strength of fresh, completely purified oil is several times as high as that of old contaminated oil.

The dielectric strength of transformer oil decreases due to:

- presence of moisture in oil;

- presence of entrapped gas;

- presence of mechanical impurities.

Water droplets are the most dangerous impurity, because they are distributed throughout the liquid dielectric volume. When voltage is applied, water molecules are polarized as oriented by the direction of the electric field vector and forming chains of higher conductivity. A dielectric breakdown occurs along these chains. If the transformer oil volume contains only 0.01% of moisture, the dielectric strength decreases 3 times at once.

If a liquid dielectric contains gas bubbles, it poses a danger by way of fast-evolving ionization processes. This is due to the fact that the dielectric strength of gases is lower than the liquid dielectric strength. During the ionization of entrapped gas, it is observed to grow in size, and the oil is locally overheated. Gas channels evolve inside the oil, and a dielectric breakdown occurs along them.

Soot, metal particles, and fragments of solid transformer insulation also influence a decrease in the dielectric strength of oils. Cellulose insulation fibers absorb the moisture that the oil contains, bridge oil insulating gaps, and form the channels through which a breakdown occurs.

Special filtration, drying, and degassing units are used to increase the dielectric strength of transformer oil.

Processes for increasing the dielectric strength of transformer oil

In the energy sector, special equipment is applied to increase the dielectric strength of transformer oil. Filtration units allow removing the mechanical impurities from the oil. Such equipment usually contains a few filters of different filtration fineness. First, the oil passes through a coarse filter and then through a fine filter. There can be more than two filtration stages.

Oil heating and exposure to vacuum are used to remove water and gases. After heating, moisture and gases evaporate from the oil surface and are removed using a two-stage vacuum system in operation.

When it is necessary just to dry the oil, units with zeolite cartridges are used. Zeolite sorbent is good at absorbing the water from the oil and retaining it reliably in its granules.

Applying such equipment on a standalone basis or in package increases the dielectric strength of transformer oil.

Difference between dielectric strength and breakdown voltage of transformer oil

In addition to dielectric strength, there is another basically similar parameter of transformer oil — breakdown voltage. Why have we mentioned that? These two parameters are often equated. Actually, they are similar, but not the same. If dielectric strength is the minimum electric field intensity at which an oil breakdown occurs, then breakdown voltage is the maximum voltage that the oil can withstand before a breakdown comes about.

The dielectric strength and breakdown voltage of insulating oil are related with each other by a single formula. Calculating the dielectric strength requires that breakdown voltage be divided by dielectric thickness.

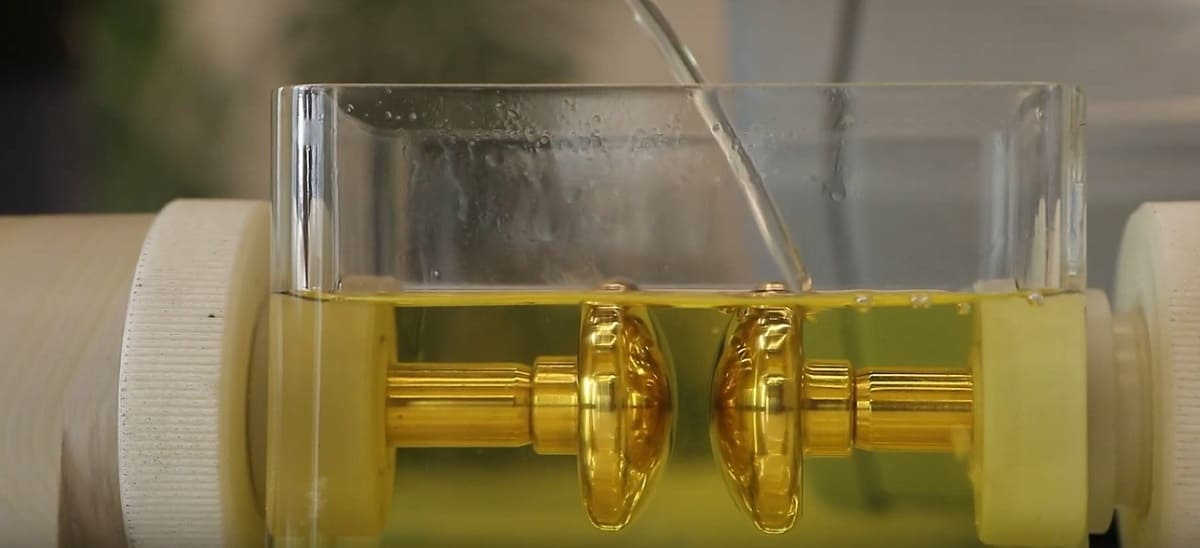

Dielectric strength measurement

In practice, dielectric strength measurement normally replaces breakdown voltage measurement. It calls for using a high-voltage transformer, a measuring cell made from insulating material, two electrodes, and transformer oil to be tested. The oil is poured into the cell after which the voltage is smoothly raised on the secondary winding of the transformer until a breakdown of the oil channel between the electrodes has occurred. Several measurements are taken on a non-continuous basis and processed afterwards by statistical methods with the final value of breakdown voltage obtained.

Different standards for breakdown voltage measurement may be applicable in different countries. But the algorithm remains as set forth above. There may be differences only in the shape of electrodes, the electrode spacing, the intervals between adjacent measurements, etc.